Apparently We All Know Vaults Flood

In February of 2017, Safe-T-Cover held a webinar on waterworks best practices and backflow installation options. Civil and mechanical engineers as well as water purveyors from across the country attended. We discussed the current trends, the different backflow preventer installation designs and afterwards held a lively question and answer session. While we were discussing utility vaults and vault flooding, we asked the audience two poll questions. We first wanted to know if those in the industry are aware of the prevalence of flooded vaults. The second question was about the potential cross connection created in a flooded vault. The results of the poll questions leave us wondering why the vault remains an acceptable design. You may be just as surprised as we initially were to read about the results.

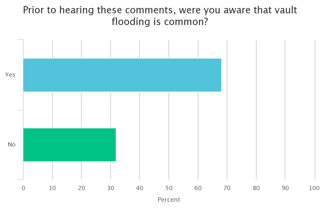

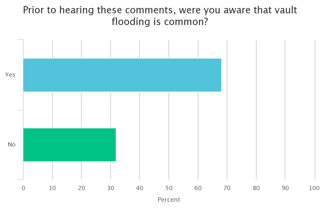

Poll question : Were you aware vault flooding is common?

Safe-T-Cover has been meeting with water jurisdictions and testers in cities across the country and are consistently told that a flooded vault is a common occurrence. We've heard from city backflow prevention managers, testers, and instructors about just how common. Recently, we even had a respected tester write an article about the dangers of vaults and vault flooding. You can read it here. In a recent phone conversation with a veteran cross control specialist from a large Midwestern city, a flooded vault was described as more common than a dry vault. Since it appears to be such common knowledge, we weren’t surprised when 70% of the webinar audience answered yes to this question. Most everyone in the industry seems to know that underground vaults for backflow preventers tend to flood. That's all fine and good, but we needed to learn more to find out why vaults are still the most common place to specify and install backflow preventers.

We'd like to hear your thoughts on underground vaults and flooding too. Click here to weigh in.

Poll question 2: Were you aware that a flooded vault creates a potential cross connection?

Water jurisdictions look to the USC Foundation for Cross-Connection Control and Hydraulic Research (USC FCCCHR) as a go to resource.  First in the Summer 2005 edition, next in the Spring 2014 edition, and again in the recent Winter 2016 edition of Cross Talk, USC recommends that all backflow assemblies be installed above grade. Here is what they had to say in 2014, "When a backflow preventer is installed below grade, the vault or pit in which an assembly is installed may fill up with water—possibly contaminated water. The water in the pit could create a cross-connection between the water in the pit and the backflow preventer through the test cocks. This may occur whether the test cocks are opened or closed." The prevention of a cross connection is the very reason this expensive backflow assembly is installed in the first place. Think about the quality of the water in a vault. Having that nasty water drawn into the customer’s drinking water or back into the public drinking water is what we all want to avoid, right?

First in the Summer 2005 edition, next in the Spring 2014 edition, and again in the recent Winter 2016 edition of Cross Talk, USC recommends that all backflow assemblies be installed above grade. Here is what they had to say in 2014, "When a backflow preventer is installed below grade, the vault or pit in which an assembly is installed may fill up with water—possibly contaminated water. The water in the pit could create a cross-connection between the water in the pit and the backflow preventer through the test cocks. This may occur whether the test cocks are opened or closed." The prevention of a cross connection is the very reason this expensive backflow assembly is installed in the first place. Think about the quality of the water in a vault. Having that nasty water drawn into the customer’s drinking water or back into the public drinking water is what we all want to avoid, right?

Here’s where things get interesting. When we asked poll question 2, 70% answered yes, they were aware that a flooded vault creates a potential problem. So, what we learned from these two questions is the industry, both design engineers and water purveyors, is well aware that vaults flood and that a potential cross connection is created when this happens. We simply don’t understand this attitude if clean drinking water is a top priority and concern. In fact, we'd like to hear your opinion on the flooded vaults and the problem they can cause. Please click here to answer a couple questions and leave us your comments.

Using This Accepted Design Means Accepting Cross Connections

We know change is not easy, especially when the vault has been an accepted design for decades. We also know most water jurisdictions lack the above ground details necessary for you to design with confidence an above ground backflow assembly. We know the vault is more aesthetically pleasing than an above ground enclosure. Lastly, we know the backflow design is a small aspect of your civil engineering design scope. However, are all those things more important than backflow prevention? If we know the potential risks of vaults and fail to act, are we perpetuating a design that puts clean drinking water at risk?

As a water purveyor, we wonder why the practice is still accepted. We all depend on clean drinking water each and every time the faucet is opened. Civil engineers are willing to design differently but standard details often do not exist. We can help you develop a comprehensive set of standard details. Contact us to schedule a call to discuss your water jurisdiction and how we can help.

The status quo guides many decisions in our work and personal life. But doing so can sometimes put us in a compromised position. The next time you design or approve a backflow preventer installation ask yourself what the best and most effective solution would be.